Fundamentals

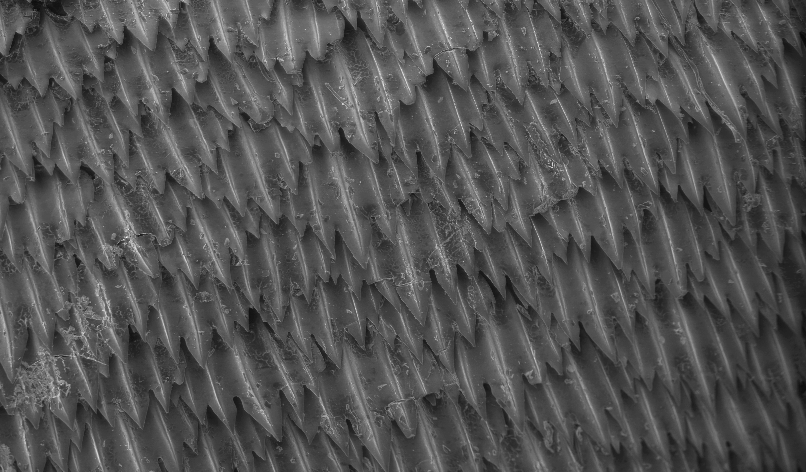

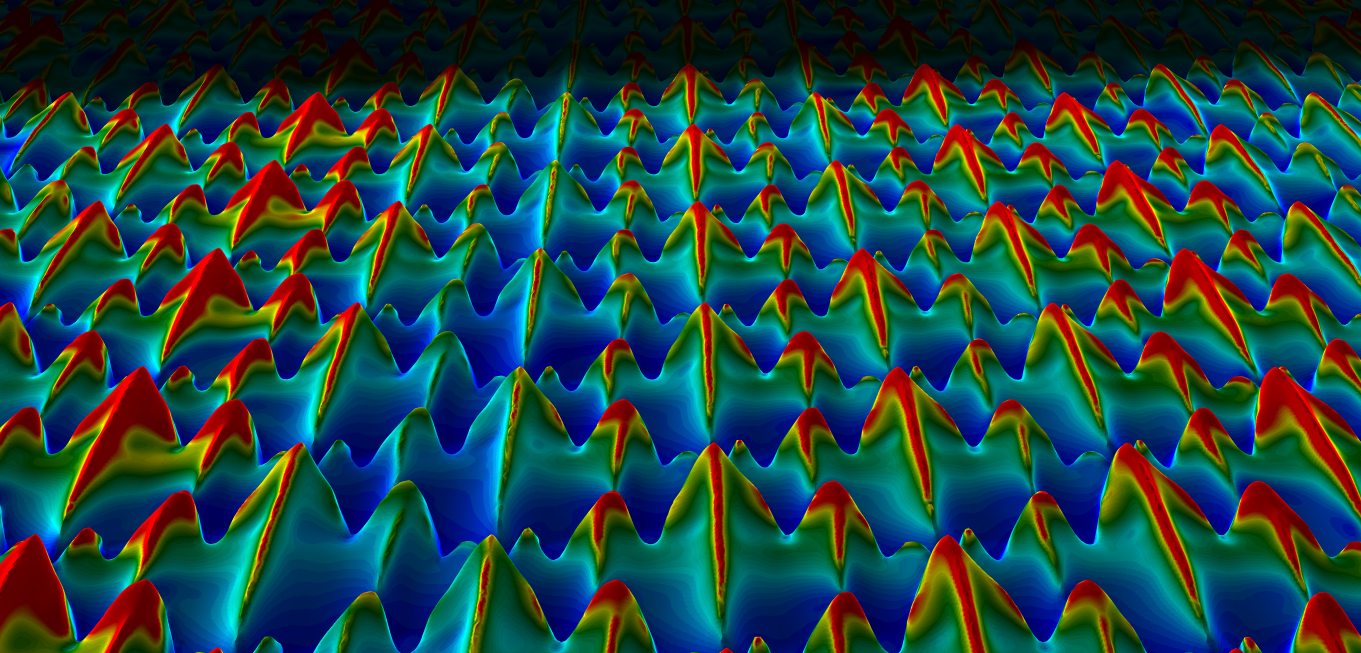

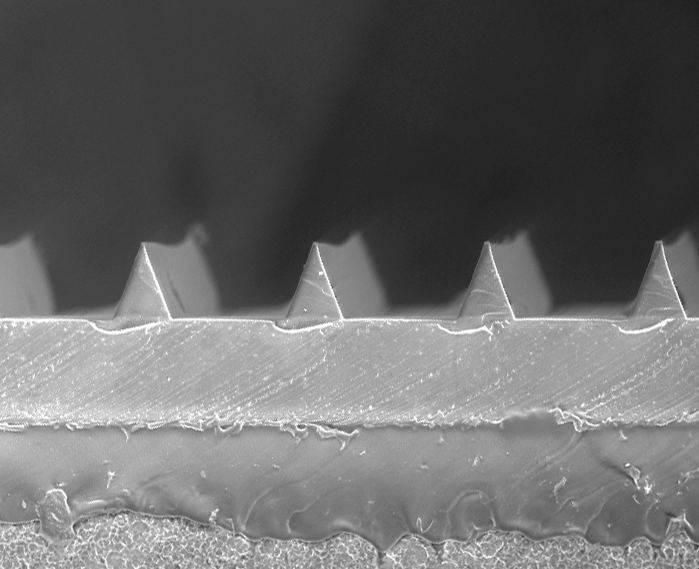

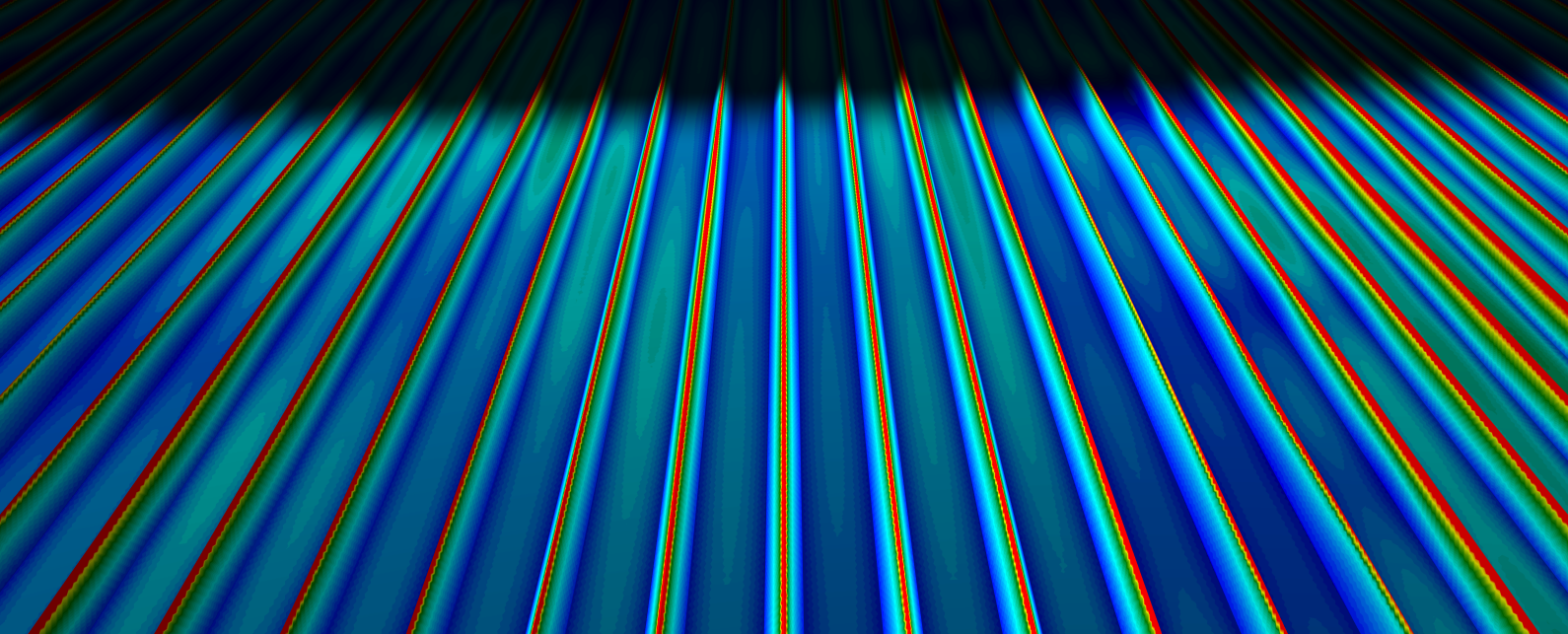

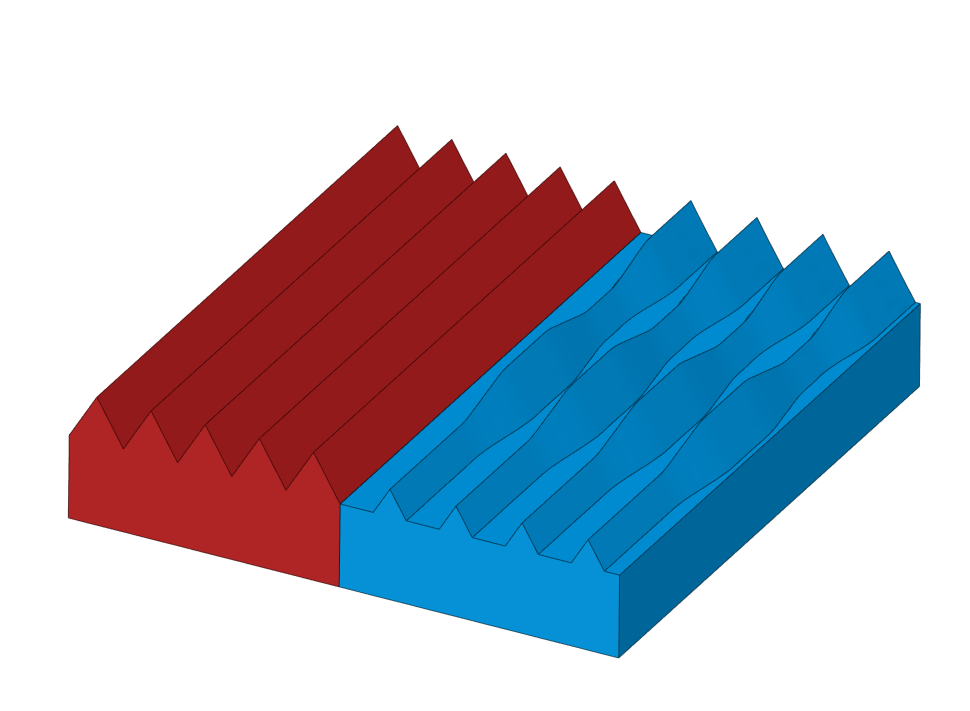

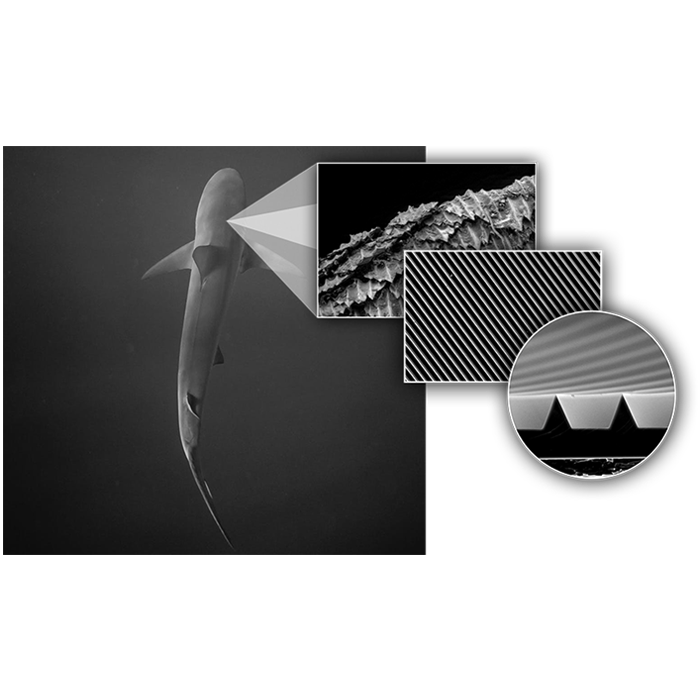

Shark skin looks smooth and ordinary from a regular perspective. As soon as it is inspected through the magnification lens of a microscope, it reveals a whole different shape. Tiny teeth and grooves cover the surface and give it a look and feel, similar to the surface of sandpaper. These “dermal denticles” are scales which vary in their size, depending on their location on the shark. Furthermore, different species show different denticle allocations and shapes. A common characteristic of these grooves is their orientation parallel to the water flow over the skin.

The various capabilities of the shark skin structure provide sharks with significant benefits and are a reason for their evolutionary superiority. Benefits of the denticle scales are on the one hand a better protection against competitors, or on the other hand advantageous fouling properties, which means less attachment of organic material like bacteria or algae.

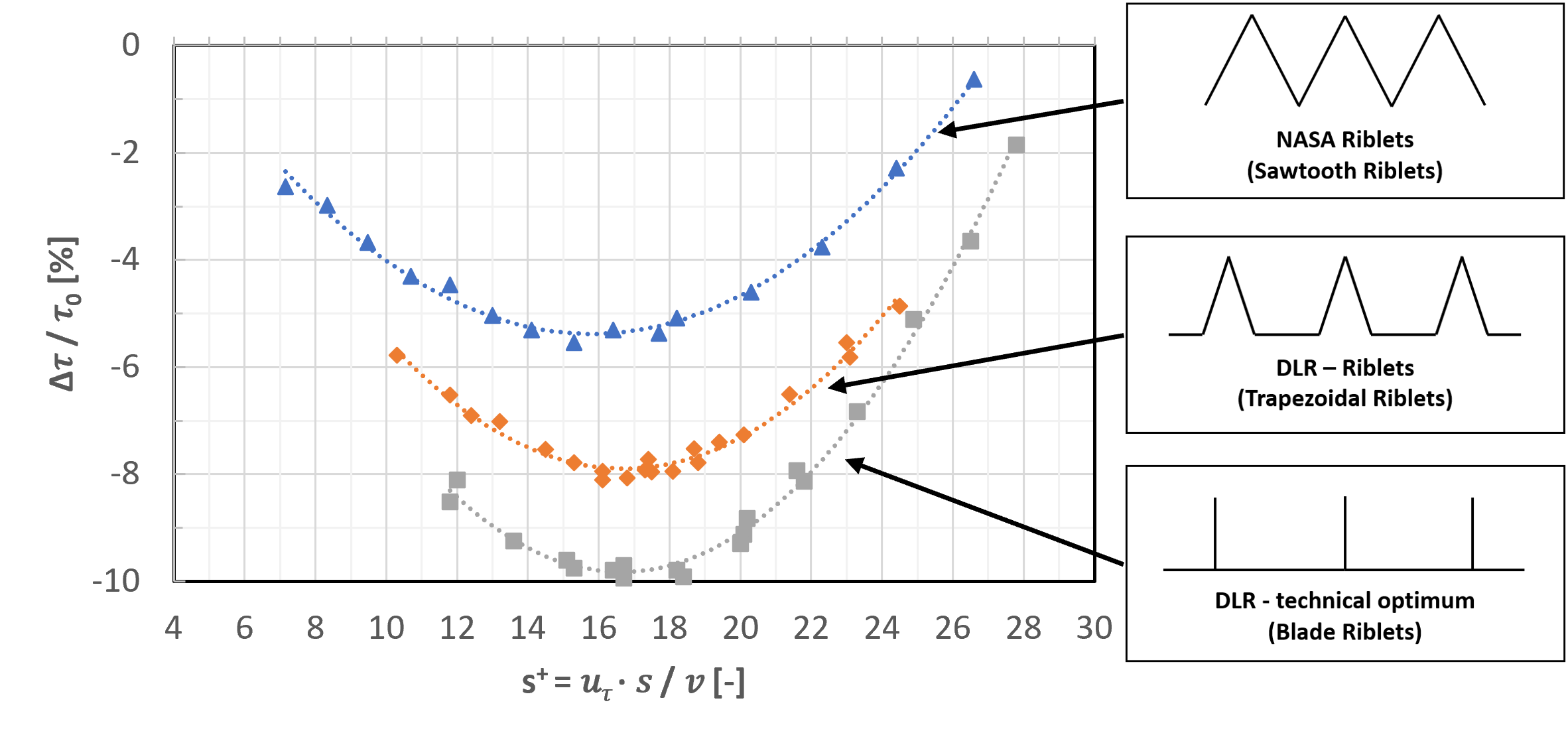

The main function of the special surface structure is to reduce skin friction while swimming. Hereby, sharks have an increased swimming speed and save energy. The discovery of this capability was the starting point for studying Riblets and led to development of technical applications.